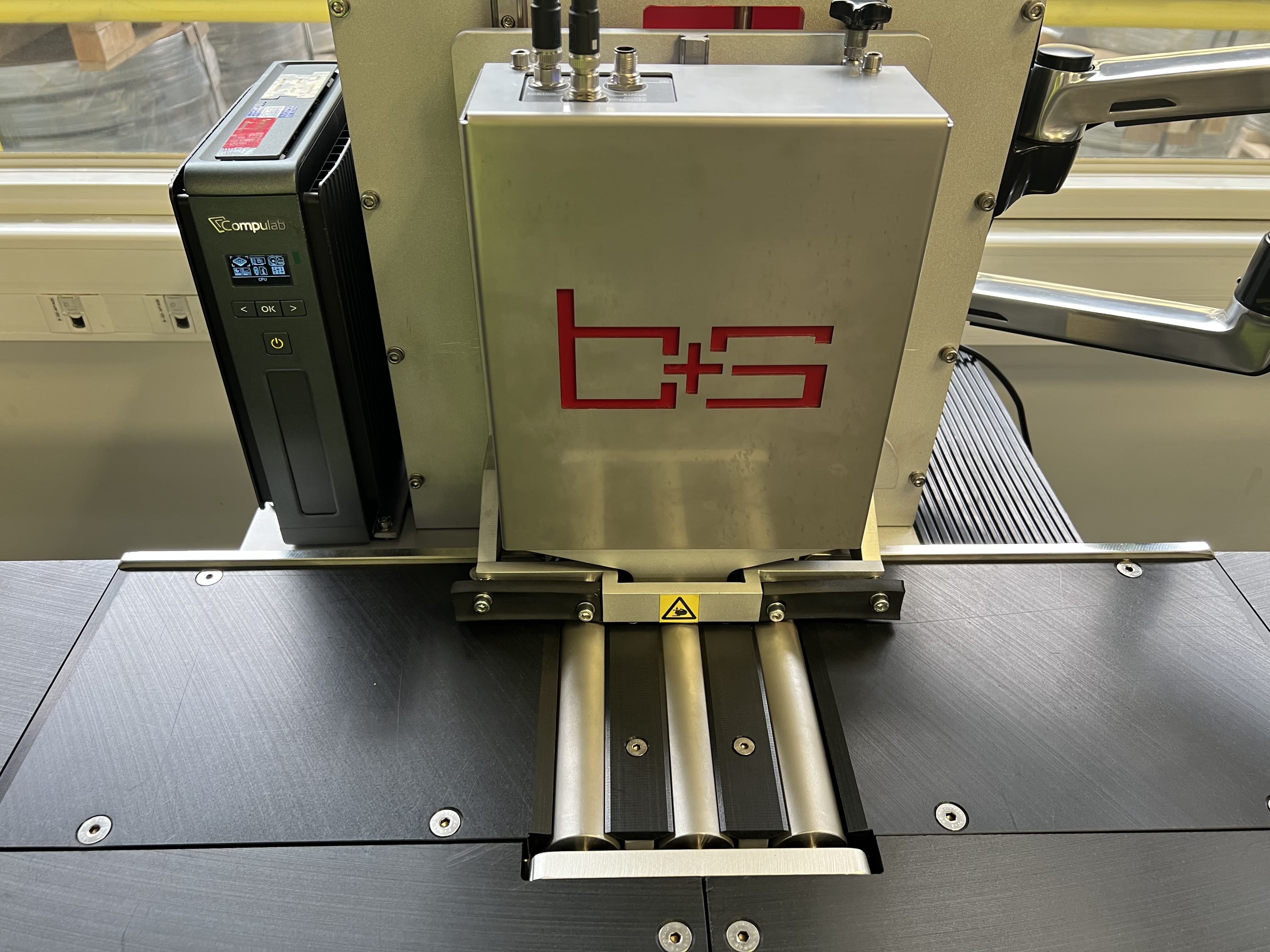

Introducing the VRWSP 900 Strip Width and Strip Position Measurement System with Distance Measurement.

Vollmer.se is excited to present the VRWSP 900 system, a revolutionary solution in the realm of precision strip width and strip position measurements. This cutting-edge system is equipped with advanced radar technology, seamlessly combining a transmitter and receiver antenna, harnessing millimeter-wave technology akin to the infrastructure of 5G cellular networks. Its exceptional versatility, wide frequency range, and precise beam focusing position it at the forefront of precision measurement technology.

What distinguishes the VRWSP 900 is its remarkable capability to accurately identify metal strips while remaining impervious to interference from other materials. Even in the presence of electrically conductive liquids, the system's precision remains unwavering. It exclusively detects metal strips with reflective edges, making it the perfect choice for a broad spectrum of strip width and strip position measurement applications.

The measurement process begins at a distance of 250 mm from the sensor window, a distance that is fully customizable, ensuring pinpoint accuracy even when metal strips are in close proximity. For strip widths of 0.2 mm, the measurement endpoints are situated at approximately 700 mm from the sensor window, while for a width of 0.05 mm, they are positioned around 550 mm from the sensor. The system offers a total width measurement range of 900 mm, with the flexibility to tailor it to custom width ranges, designed to meet your specific requirements.

What truly sets the VRWSP 900 apart is its exceptional ability to accommodate variations in the passline, even up to 20 mm, with only a minimal impact on the indicated strip width. This adaptability to address variations in the distance from the sensor to the strip edge positions it as a remarkable choice for strip width and strip position measurement systems. When precision is of utmost importance, the VRWSP 900 system stands as the unrivaled solution, setting new standards in the realm of industrial technology.