Shape Meter Measurement Systems

Why strip shape is critical to product quality

In strip processing lines, shape deviations are a frequent cause of downstream defects such as edge waviness, buckling, slitting inconsistencies, and length variations. These issues directly impact product quality, yield, and compliance with customer specifications.

Industries such as automotive, aerospace, and electronics require precise and traceable shape control to meet strict flatness tolerances. Accurate and continuous measurement of strip shape is therefore essential for process stability, quality assurance, and reduced scrap rates.

What is a shape meter measurement system?

A shape meter measurement system is a specialized sensing solution designed to quantitatively assess and control the flatness of metal strip during processing. It provides real-time data on shape deviations, expressed in I-units, where 1 I-unit equals a length difference of 10 µm per meter of strip width.

Det är viktigt att skilja mellan planhet och nivelleringsgrad. Nivelleringsgrad avser höjdavvikelser på en plan yta, medan planhet beskriver den interna spänningsfördelningen över bandets bredd. Denna fördelning avgör hur bandet uppför sig under dragspänning—hur det slits, böjs eller lindas—och i slutänden om det klarar slutinspektionen.

Full-spectrum shape measurement from Friedrich Vollmer

Friedrich Vollmer offers a comprehensive portfolio of solutions for precise, real-time shape measurement across all key production environments:

BFI shape meter roll

Developed under license from the VDEh-Betriebsforschungsinstitut (BFI), the BFI roll features a solid steel roll body with a homogenous outer surface. Inside, piezoelectric sensors monitor stress differentials as the strip passes across the roll.

Typically replaces an existing deflector roll

Available with various surface coatings (steel, tungsten carbide, rubber, chrome)

Regrindable using standard roll grinding equipment

Measuring zone widths from 17 mm and up, fully customized

TCP/IP data communication enables seamless integration into modern plant networks

Segmented shape rolls for stretch-bend levelers

In tension-leveling and straightening lines, Vollmer's segmented shape rolls offer zone-based measurement through individual sensorized segments:

Each segment is a coated ring rotating on low-friction bearings around a fixed central axis

Strain gauge sensors inside the axis measure radial force per zone

Operates without auxiliary drive—ideal for low strip tension or small wrap angles

Communication supported via TCP/IP, Profinet, analog and digital I/Os

Automatic flatness control (AFC)

Measuring strip shape is only the first step. Vollmer systems also support Automatic Flatness Control (AFC), closing the feedback loop between sensor data and actuator response.

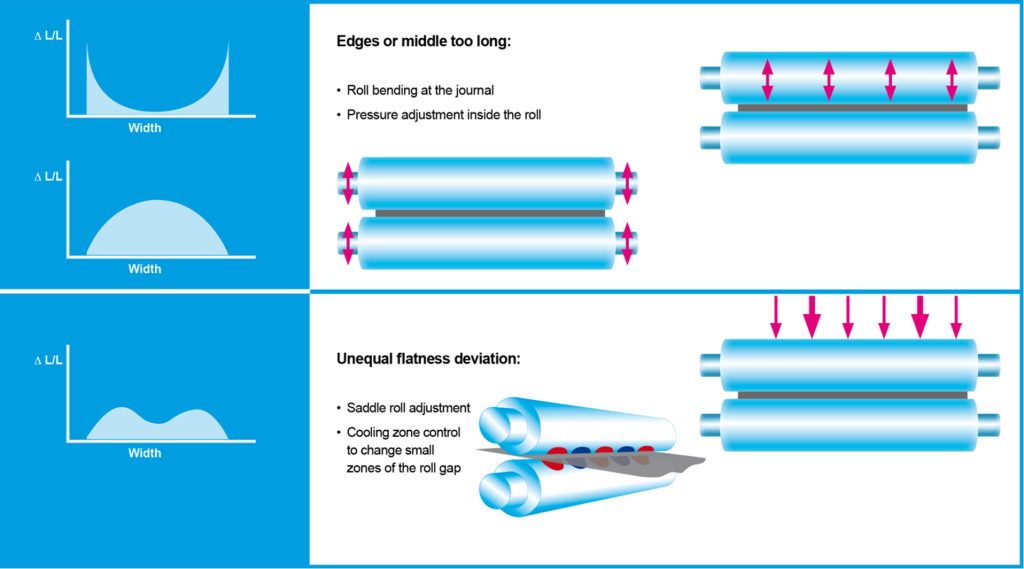

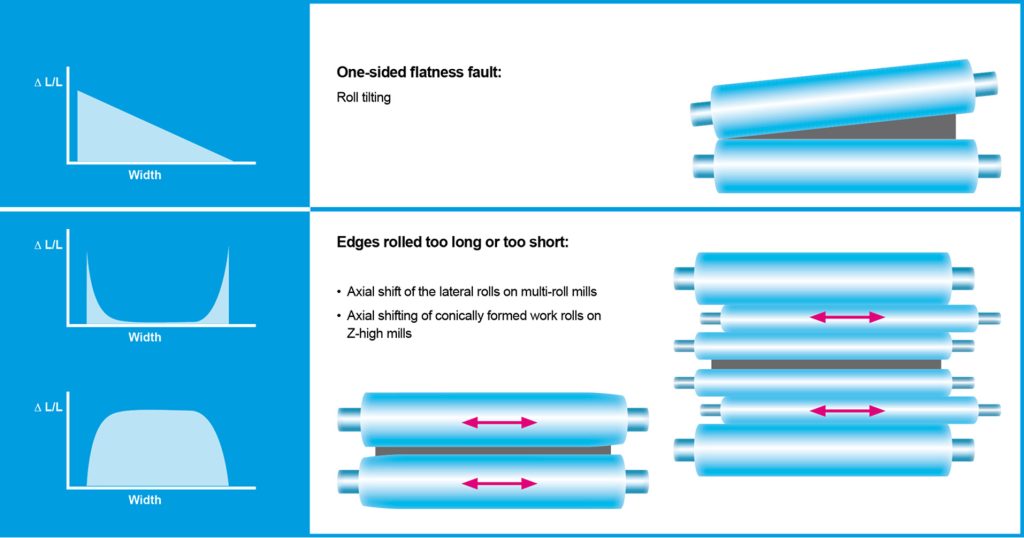

When integrated into mills equipped with adjusting actuators—such as:

Work roll bending

Intermediate roll shifting

Roll tilting

Zone cooling systems

—Vollmer’s AFC module dynamically adjusts rolling parameters to maintain flatness within defined I-unit thresholds.

This leads to:

Fewer strip breaks

Reduced out-of-spec production

Higher line speeds with confidence

Improved customer satisfaction through documented flatness compliance

Typical control accuracy of ±4 I-units is achievable relative to the nominal shape curve, making AFC a cornerstone for producers in aerospace, automotive, and electronics steel grades.

Ready to take control of strip shape?

Precision strip shape measurement is no longer optional—it’s essential to meet the demands of today’s high-performance industries. Whether you're running high-speed cold mills or delicate tension leveling lines, Vollmer's shape meter measurement systems give you the data and control needed to optimize productivity and deliver certified quality.

Contact us today for a tailored consultation and discover how shape measurement can transform your line performance.